The process of modern industrial development is continuous improvement and upgrading, the future industrial automation development is bound to the production equipment intelligent, production process automation development, the realization of intelligent industrial automation will fully realize the production process automation, to ensure that the production and manufacturing and even the entire life cycle of the product coordination and cooperation between the various fields of complete intelligence, to help production-oriented enterprises to achieve the perfect transformation from "scale manufacturing" to "intelligent manufacturing."

In the process of the development of advanced manufacturing technology, a number of technology concepts and practices related to intelligent manufacturing have emerged, among which the most direct and closely related to intelligent manufacturing are digital technology, network communication technology, information technology, automation technology and artificial intelligence technology, as well as agile manufacturing, lean manufacturing, network manufacturing, digital manufacturing and so on. the application and practice of these technologies play an important supporting role in the development of intelligent manufacturing, but at the same time they are different from intelligent manufacturing.

Intelligent Production ,IM , also known as intelligent manufacturing, is an integrated human-machine intelligent system composed of intelligent machines and human experts, which can carry out intelligent activities in the manufacturing process, such as analysis, reasoning, judgment, conception and decision-making. By working together with intelligent machines, we can expand, extend, and partially replace the mental work of human experts in the manufacturing process. It extends the concept of manufacturing automation to flexible, intelligent and highly integrated.

intelligent manufacturing is based on the research of artificial intelligence, it is generally believed that intelligence is the sum of knowledge and intelligence, the former is the basis of intelligence, the latter refers to the ability to acquire and apply knowledge to solve. intelligent manufacturing should include intelligent manufacturing technology and intelligent manufacturing system, intelligent manufacturing system can not only enrich the knowledge base in practice, with self-learning function, but also collect and understand environmental information and their own information, and analyze and judge and plan their own behavior.

with the improvement of product performance and its structure of complexity, refinement, and function diversification, the product contains a sharp increase in the amount of design information and process information, followed by the production line and production equipment inside the information flow increased, manufacturing process and management of information is bound to increase, thus promoting the development of manufacturing technology hot spots and frontiers, to improve the manufacturing system for explosive growth of manufacturing information processing capacity, efficiency and scale.

Advanced manufacturing equipment does not work without the input of information, and flexible manufacturing systems(FMS)stop working as soon as the source of information is cut off. Experts believe that manufacturing systems are changing from energy-driven to information-driven, requiring manufacturing systems to be flexible and intelligent, otherwise it would be difficult to handle such a large and complex amount of information.

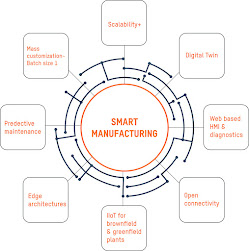

Second, rapidly changing market demands and a complex environment of intense competition also require manufacturing systems to demonstrate greater flexibility, agility, and intelligence. As a result, intelligent manufacturing is receiving more and more attention. Smart Manufacturing consists of many intelligent components and other related basic components, as shown in Figure 1. Smart Manufacturing can be understood as:

1)develop automated production lines and complete sets of devices based on manufacturing intelligence in the production and manufacturing dimension.

2)Incorporate them under the managementof the Enterprise Business Operations System (ERP)and manufacturing execution system(MES).

3)Establish a perfect CAD,CAPP,CAM based PDM, PLM, And extended to the product after-sales technical support and services.

on the basis of in-formalization and automation, the knowledge of experts is continuously integrated into the manufacturing process to realize the intelligent design process, intelligent manufacturing process and intelligent manufacturing equipment, and to realize anthropomorphic manufacturing, with the aim of making the manufacturing process more perfect judgment and adaptability, improving product quality, productivity, and will significantly reduce the consumption, energy consumption and emissions of the manufacturing process.

The internet of things is an important field of intelligent manufacturing, in recent years, china has made a number of innovative achievements in the high-end sensors, chips, communication protocols and other fields of the internet of things, in the transportation, logistics and other fields of application demonstration solid progress, and gradually explore an important way to achieve the integration of the two.

The use of internet of things monitoring and monitoring of the production process, the company's finished products, production processes, environment, security, power five aspects of thousands of (sets) of equipment into a network, and enterprise LAN, internet, mobile network integration, to achieve control integration.

PCS, MES functions related to manufacturing production equipment and production line control, scheduling, scheduling, etc. are implemented through physical information systems, which are closely linked to the Industrial Internet of Things.

From the product formation and product life cycle service dimension, but also need to have intelligent raw material supply, intelligent after-sales service, constitute real-time interconnected information exchange.

No comments:

Post a Comment