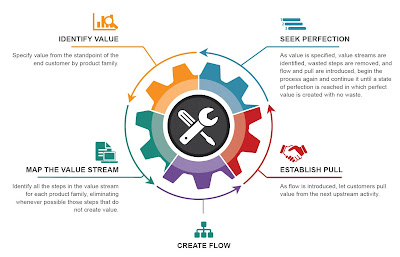

Lean provides tools and processes to eliminate waste from the manufacturing process resulting in improved efficiency, effectiveness, and profitability. The Lean manufacturing is all about the optimization of processes by eliminating waste and lowering costs while adding value to the end product.

As industry players begin to struggle to compete in the global marketplace , Lean Manufacturing is delivering success for them by increasing competitiveness and customer satisfaction. How can?

As we know, Lean Manufacturing works by cutting and minimizing undeserved work activity while the process is running. Not only that, here are 4 reasons why your company should consider Lean Manufacturing techniques:- Streamline corporate processes Implementing Lean allows manufacturers to streamline their processes across all parts of the organization, from front office to distribution area. Efficiency is done and make the work more leverage. This results in reduced production costs and increased sales acceleration to target markets.

- Eliminating waste Lean discusses the Nine Wastes: movement, inventory, waiting time, transportation, information, quality, overproduction, process, and creativity. By eliminating waste in various areas, companies have the opportunity to cut time spent on unnecessary tasks.

- Build team commitments When implementing Lean operations, the company must recognize that there is a need for change and requires the focus of all team members. In many cases, while utilizing Lean techniques, the manufacturing process can be assessed as a whole that can build teamwork.

- Continuous work Lean's key element is "continuous improvement." This means that opportunities to become more efficient are continuous in every process.

Financial Benefits

After reduced waste there is certainly an increase in corporate profits, especially when Lean's principles are properly regulated within the organization. Satisfied customers will make business run smoothly. Reduction in waste and production defects provides improved product quality and ensures higher profits.

Giving satisfaction to workers can make a business grow well in the long run. Lean Manufacturing is a business philosophy that has proven to be very successful because it can reduce costs, eliminate waste, increase productivity, maintain quality levels so as to increase your profits significantly.

No comments:

Post a Comment